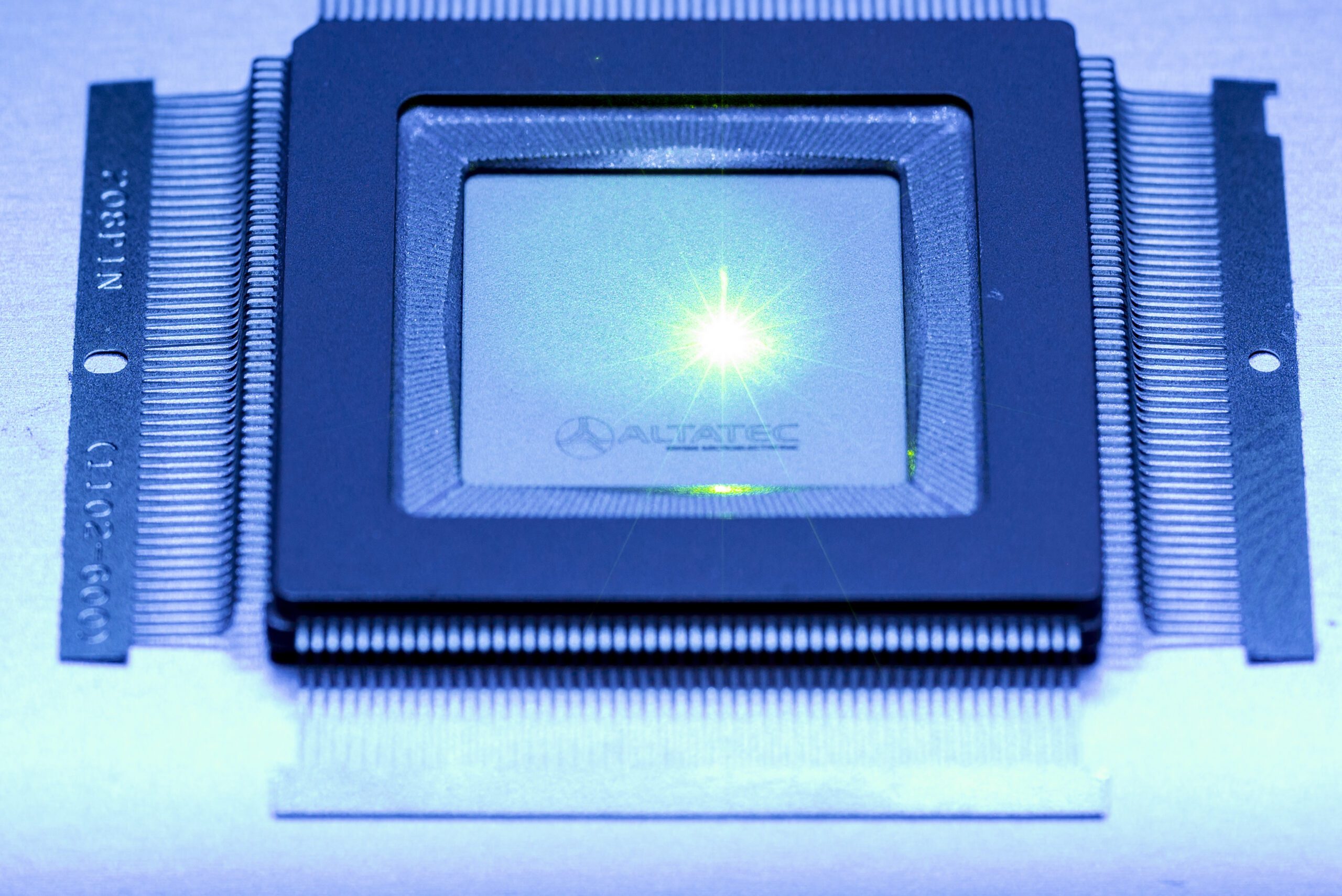

Laser trimming

The laser trimming systems from 4CS-Laser have been designed to meet our requirement. The modular system has pulsed laser sources with different wavelengths and innovative optical components. In addition, it has a freely programmable (open source) software designed to meet the individual customer requirements. The laser system can easily take on any kind of trimming tasks and operate at a hight throughput. It can also be used for mark substrates with number or abstract patterns, such as company logo, for example.

You will be redirected to an external site.

Technical properties

- Quick operational readiness

- Very large working range and can be used on almost all substrates (high throughput)

- Quick product change-over

- Programmable, high-power needle test adapter

- Freely programmable software (programming options with Open Source)

- Compact, modular structure. Reduction of negative thermal effects on the laser performance

- Integrated 2.5D laser unit with automatic calibration function (two different lasers or two of the same lasers can be integrated)

Specifications

Applications

- Passive adjustment of thick and thin film resistors

- Passive adjustment of capacitors

- Active trimming of sensors and oscillators

- Active circuit adjustment in amplifier circuits (offset, gain, CMRR)

- Digital adjustment by cutting through PCB tracks

- Lettering and markings on surfaces

- Trimming/Marking on inclined and curved surfaces or on different levels with the help of the electronically adjustable focus (2D/3D trimming and marking)

- Component tests, where the machine can be used as a test system with or without laser processing