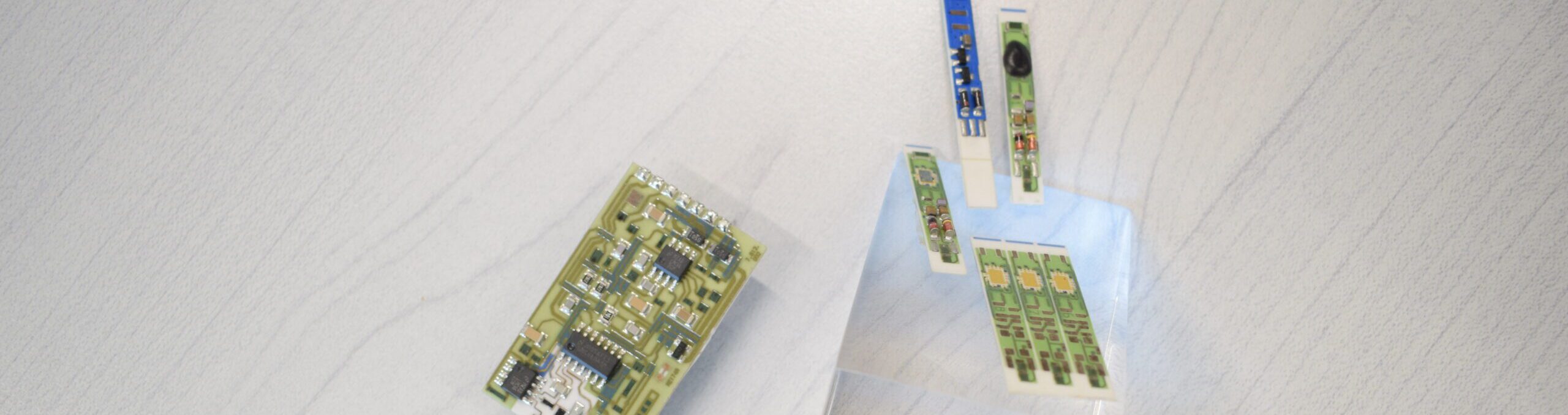

Thick-film hybrid technology, hybrid technology and hybrid circuits

Thick-film hybrid technology (hybrid technology) is a construction and bonding technology used to manufacture so-called hybrid circuits. By applying/printing conductive or resistor pastes, product-specific coatings with different levels of conductivity can be achieved. Most substrates made from aluminium oxide or LTCC can be used as carriers. The conductive surfaces and tracks are applied by means of a screen printing process and then burnt in at very high temperatures of around 850°C.

Like with epoxy printed circuit boards, the circuit board of a hybrid circuit can be more or less freely designed. Track can also cross and be routed to other layers or even to the back of the substrate by means of connection points or vias. Hybrid circuits present significant advantages in comparison to epoxy printed circuit boards. Hybrid printed circuit boards can be assembled with discrete components and even resistors and capacitors can be integrated into the layout thanks to the wide variety of printing pastes.

The resistance and capacitor values of printed circuits can vary by batch. They can, however, be precisely adjusted or trimmed either passively (direct measurement → passive trimming) or actively (by measuring part of the output signal when the circuit is in full operation → active trimming) to the desired value with a laser trimmer before or after assembly.

Another major advantage of hybrid circuits is their high electrical insulating resistance and high thermal conductivity. It makes them perfect for high-resistance circuits such as charge amplifiers or high-power assemblies, e.g. high-power LED modules, where a good thermal coupling to a cooling element is essential.

Technical properties

- Layout engineering

- Stencils and screen printing

- SMD and COB assembly

- Wet chemical and plasma-chemical cleaning

- Laser trimming

- Testing

Specifications

Applications

- Combined circuits by means of COB and SMD

- Highly insulating circuits

- Medical products

- Sensor circuits

- Circuits that must be operated at very low temperatures

- Circuits that have been actively or passively adjusted by means of laser trimming

- Temperature sensors

- Power resistors and resistor networks

- LED modules