Surface mounting

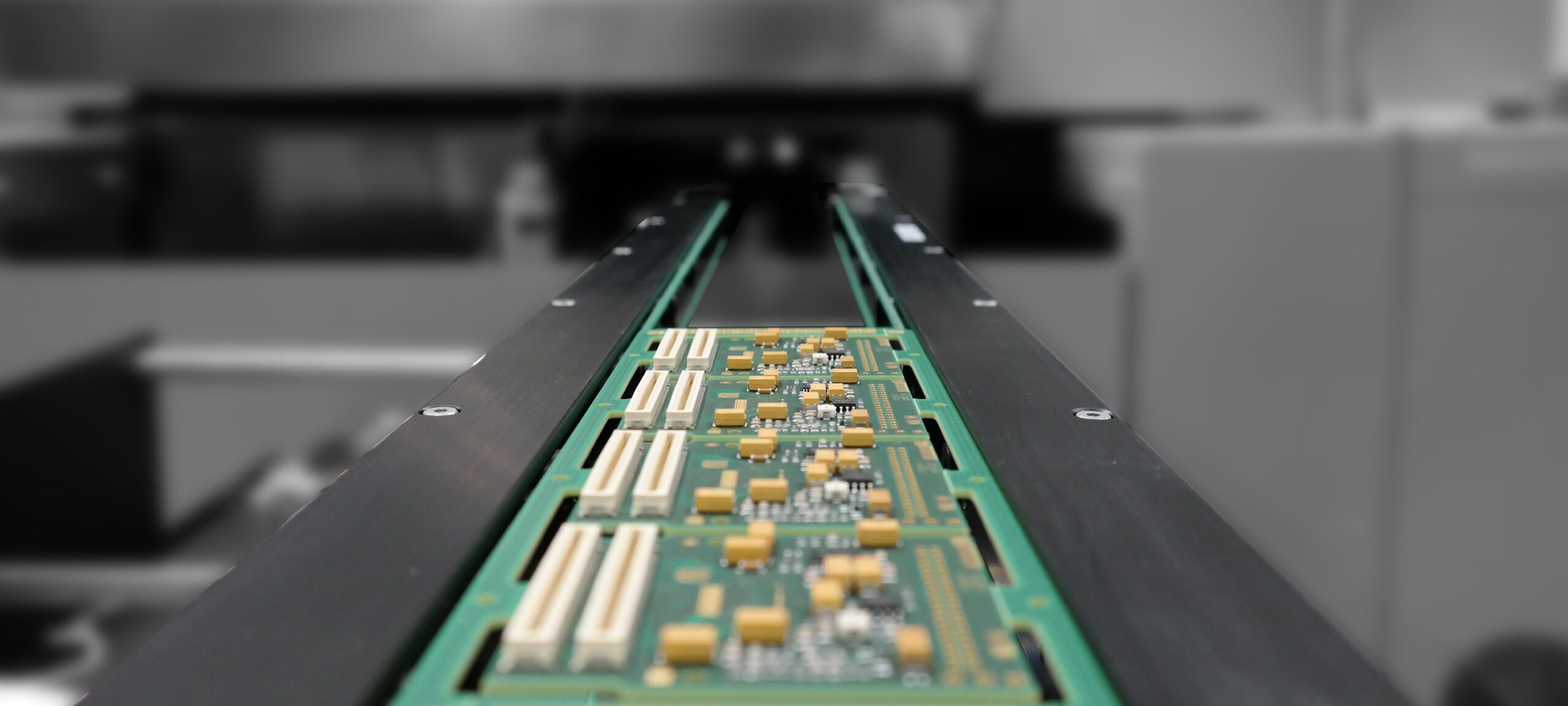

SMD (surface mounted device) components have solderable connections that can be used for surface mounting and they can be fed into the machine in different packaging units (trays, reels, blisters, etc.).

When it comes to assembling electronic circuits, SMD components have the major advantage that they can be assembled by a machine at a high throughput. With SMD assembly lines, printed circuit boards can be manufactured almost 100% automatically: from the die-casting, to the assembly of the components, through to the soldering.

The trick is to combine the SMD process and COB process so that the quality and the effort required for the assembly are ideally balanced. For example, when manufacturing complex circuits, it may make sense to apply the solder paste on the SMD line but then carry out the actual assembly and soldering on a die bonder. This is known as a mixed assembly.

Technical properties of our SMD infrastructure

- Fully automatic substrate feed line

- Fully automatic stencil printing on an Ekra SERIO 4000

- Automatic solder paste dispensing by the Altatec dispensing robot

- Fully automatic assembly on a Fuji AIMEX IIS

- Fully automatic soldering in a Rehm – VisionX-Series reflow oven

- Fully automatic soldering on a hot plate for substrates that cannot be soldered in a reflow oven

- Paste dispenser for substrates that cannot be printed

- Automatic soldering in an ASSCON vapor phase oven

Specifications

Applications

Assembly of:

- Integrated circuits, sensors, actuators, camera chips, optical components and LED chips

- Micromechanical components

- Positioning of assembly elements precise to the micrometre

- Applications (sectors, markets, examples)